Heat treatment: the key technology for superior performance

Heat treatment furnaces are crucially important industrial plants, used in a wide range of sectors, from the most demanding (such as automotive and aerospace) to the most common applications in precision mechanics and tool production.

These plants play a crucial role in the transformation of metallic materials. Through controlled heating and cooling cycles, the metal’s internal structure is modified so that it acquires the mechanical and physical properties needed to guarantee high performance, reliability and durability.

Necesidades:

Temperature control in the thermal process

Para saber más

Digital recording of process variables

Para saber más

Furnace high temperature limit switch

Para saber más

Electrical heating loads control

Para saber más

Thermal process temperature measurement

Para saber más

Operating principle

When it comes to heat treatments, batch furnaces are the most popular and appreciated solution because of their extraordinary versatility. The front opening design facilitates the loading of single components or complex batches, including items with uneven shapes or delicate materials, making the process simple and safe.

Designed for industrial applications, these devices are equipped with a closed thermal chamber with internal lining made of refractory materials, which guarantees excellent insulation and uniformity of treatment throughout the load.

With temperatures that can reach 1000°C, batch furnaces are ideal for a wide range of heat treatments, including quenching, tempering, annealing and normalising. Each process is managed according to a dedicated thermal profile, which is essential to obtain the desired metallurgical properties.

Reliable, flexible and efficient, batch furnaces are the perfect choice if you are looking for high performance and consistent results.

Requirements and Technology

In heat treatments, temperature is the most critical parameter, it must be managed with absolute precision and guaranteeing constant stability, to ensure reliable results and conformity with the highest standards.

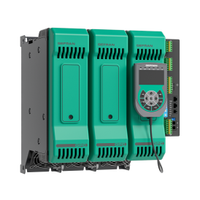

To achieve this, modern systems rely on advanced PID controllers, which are equipped with optimised algorithms and auto-tuning functions that simplify management and ensure intuitive and efficient control of the entire process. Heat can be produced through electrical resistors or gas combustion: in the first case, the temperature controller communicates with electronic Power Controllers, which modulate the resistance thermal energy with extreme precision; in the second case, the controller manages the gas valves directly, guaranteeing reactivity and safety.

But controlling is not enough: it is also crucial to record the temperature profile, especially in highly specialised sectors such as aerospace and aeronautics, where process traceability is essential to certify quality and comply with the strictest regulations.

Finally, to protect the system and ensure the safety of operators, it is essential to integrate dedicated protection devices, such as safety thresholds against overtemperatures, which intervene promptly to avoid critical situations.