Heat treatment with vacuum furnaces is an advanced process used to modify the properties of metals, ensuring high precision and quality. These furnaces operate in oxygen-free environments, avoiding contamination and oxidation in the finished product. The heart of the process is the accurate control of temperature, which can be very high, often above 1500 °C, maintained with minimum tolerances.

Necesidades:

Temperature control in the thermal process

Para saber más

Digital recording of process variables

Para saber más

Furnace high temperature limit switch

Para saber más

Electrical heating loads control

Para saber más

Temperature measurement in the thermal process

Para saber más

Operating principle

Vacuum furnaces are the ideal solution when very high precision heat treatments in a controlled and contamination-free environment are required. By removing air and oxygen from the treatment chamber, these systems eliminate the risk of oxidation and ensure maximum purity of materials, minimising post-treatment processing.

By uniformly distributing heat, vacuum furnaces ensure homogeneous and repeatable results, which are essential for applications in the aerospace, medical, automotive and metallurgy sectors. The integration of advanced technologies for the control of temperature and pressure allows operators to manage each step of the process with extreme precision.

Electric heating, combined with smart control systems, offers high energy efficiency, optimising consumption and performance – a strategic choice if the focus is quality, reliability and sustainability.

Requirements and Technology

In vacuum furnaces, accurate temperature control is a strategic element to ensure reliable, repeatable and very high quality processes. To meet the needs of the most demanding sectors – such as aerospace, medical and automotive – advanced digital systems are used, including PID controllers, which can manage each phase of the thermal cycle with extreme accuracy.

The absence of air means that vacuum furnaces require special electrical resistors, such as graphite or molybdenum silicon (SiC) units, which can operate at extreme temperatures. In this context, the control of electrical power becomes crucial.

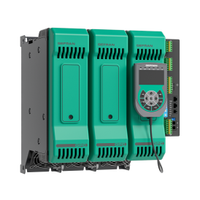

This is where Power Controllers come in. These smart devices are designed to optimise energy dynamically and responsively, improving performance, safety and energy efficiency. This technology not only guarantees excellent results, but also a sustainable and intelligent management of the thermal process.